UVC-LED sterilization device

UVC-LED sterilization devic

Use a specific wavelength of UVC-LED to sterilize water; better care, make life healthier

Suitable for household appliances such as refrigerators, ice machines, dishwashers, water dispensers, | ||||

washing machines, toilets, etc. | ||||

Specification for UVC sterilizing lamp assembly

![]()

Model: JRS-MD56

Ⅰ Product Manual:

1、Product introduction

This product can be installed in the drum washing machine, and it can control the UVC irradiation through the main control board to achieve the sterilization purpose. It can also be installed in a suitable position inside other electrical products for use as related sterilization products.

2、Introduction of UVC and principle of sterilization:

UVC is a light wave with a wavelength of 200-310nm. It is called C-segment ultraviolet or bactericidal ultraviolet. Due to its short wavelength and high energy, it can destroy the molecular structure of DNA(deoxyribonucleic acid) or RNA(ribonucleic acid) in microbial(Bacteria, viruses, spores and other pathogens) cells in a short time,cells cannot be regenerated, and bacteria and viruses lose their ability to reproduce themselves. Therefore, UVC wave range products can be widely used for sterilization and disinfection of water and air.

3、Advantages of UVC products:

>>Own advantages

Ø No change in water quality, no secondary pollution;

② Safe, reliable and low power consumption;

③High-efficiency sterilization, up to 99%, the highest sterilization spectrum; ④Small size, easy to install and carry;

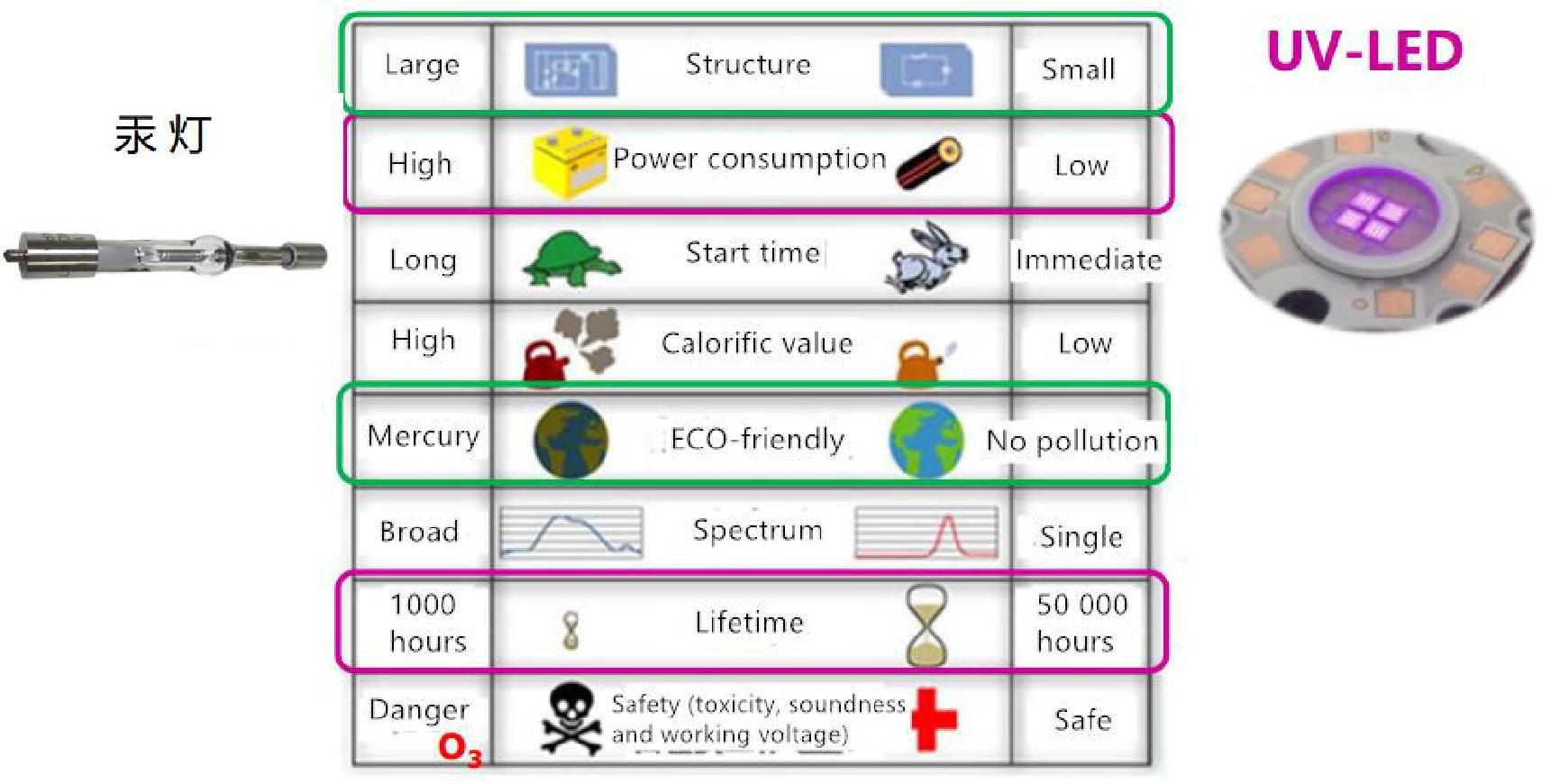

>>Advantages over traditional mercury lamps

4、Main application description of the product

![]()

①The product can be used in household appliances and other environments that need to be sterilized, and has the effect of sterilizing and disinfecting the environment.

②The product is small in size, takes up little space, and is easy to assemble.

③ The product uses DC low-voltage power supply, is equipped with plastic parts and double-layer quartz lampshade, has double-layer insulation, and will not cause hidden electrical safety hazards. ④Low product power and low energy consumption.

⑤When used in conjunction with other sterilization devices and gas or water circulation systems, it will have a better effect.

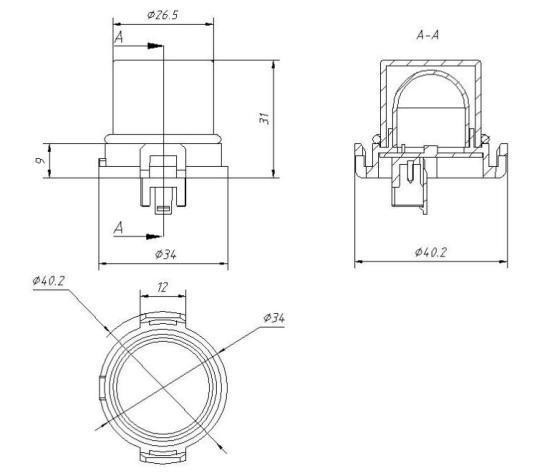

Ⅱ Product picture and size

1.Product physical picture

2.Product size chart

Ⅲ The main technical parameters:

![]()

No. | Item | Technical parameters | |||||||

1 | Rated Voltage | DC12V | ( | ~ | 110% | ) | |||

Voltage fluctuation range is rated voltage 85% | |||||||||

2 | Rated Power | ≤0.6W | |||||||

3 | UVC-LED | 270-285nm | |||||||

wavelength | |||||||||

4 | Radiated power | 1.8mW | |||||||

5 | Working | Ambient temperature:-30℃~+60℃ | |||||||

environment | Storage temperature:-40℃~+100℃ | ||||||||

6 | Connector | 1-1971921-3 | |||||||

model | |||||||||

a) The surface of the product should be smooth, without pores, | |||||||||

bumps, damage, mottling, dirt, etc .; | |||||||||

b) The connector model is correct, and the surface is free of | |||||||||

oxidation, scratches, deformation, corrosion, etc .; | |||||||||

c) There should be no obvious misalignment, excessive gap or | |||||||||

7 | Appearance | skew in the assembly of components; | |||||||

d) The product needs to be marked with a label or laser marking | |||||||||

method. The content includes: name, model, input voltage, | |||||||||

input power, manufacturer, and production date. If necessary, | |||||||||

the user's special number, RoHS environmental protection | |||||||||

mark, certification mark, etc. should also be marked. | |||||||||

Electrical | When the environment is 25 ℃, the product applies AC600V / | ||||||||

8 | 50Hz between the output end and the case for 1S, the leakage | ||||||||

strength | |||||||||

current is ≤5mA, and there is no breakdown or flashover. | |||||||||

9 | Insulation | The insulation resistance of the input end of the product to the | |||||||

resistance | enclosure should be > 100MΩ. | ||||||||

10 | Drop test | The parts have dropped 10 times from a height of 750px, and | |||||||

the appearance, structure and function are normal. | |||||||||

11 | Temperature | Input DC12V, ambient temperature 25 ℃, continuous working | |||||||

rise test | for 4 hours, surface temperature rise≤45 ℃. | ||||||||

According to the provisions of GB / T2423.3-2006, the product | |||||||||

is placed in an environment with a temperature of 60 ℃ ± 3 ℃ | |||||||||

12 | Damp heat | and a | relative temperature of 90-95%. After 168 | hours | of | ||||

storage test | storage, it is placed at room temperature for 2 hrs. | ||||||||

After the test, the appearance, structure, and performance of | |||||||||

the product should be no abnormalities. | |||||||||

Vibration | In the unpowered state, place the product on a vibrating table | ||||||||

13 | with an amplitude of 1.5mm and a frequency of 10HZ-50HZ, | ||||||||

experiment | |||||||||

and maintain rigid contact. Take the vibration in up, down, left, | |||||||||

right, front and back, and three directions respectively for | ||||

30min. Remove the product after the test. Appearance, | ||||

structure and function are normal. | ||||

Test for 24h according to the provisions of Ka in GB / T 2423.17. | ||||

14 | Salt spray test | The metal part has not rusted, and the product can work | ||

normally. | ||||

15 | Heat resistance | Ball pressure test: 75 ℃ ± 2 ℃, 60min, the diameter of the | ||

of plastic parts | indented spherical surface should not exceed 2mm. | |||

Flame retardant | ||||

16 | properties of | GWFI 750℃ | ||

plastic parts | ||||

The following contents and trademarks should be on the | ||||

product packaging: | ||||

17 | Label | a. Product model, name and trademark. | ||

b. Packing quantity and weight. | ||||

c. Manufacturer and date of manufacture. | ||||

d. Anti-moisture and anti-impact signs. | ||||

A. Product component packaging should be anti-static, | ||||

shock-proof, pressure-proof, and waterproof, with no damage | ||||

on the surface, no oil stains, and no collision or extrusion. | ||||

b. A certificate of conformity must be posted on the outer | ||||

18 | Packing | packaging, including the supplier name, product quantity, | ||

specification model, material number, production date and | ||||

batch number. | ||||

c. Each batch of products must be accompanied by a | ||||

production inspection report and clearly indicated on the outer | ||||

packaging. |

JRS Components (HK) Limited

Copyright @ 2016 JRS Components (HK) Limited All Rights Reserved.